The ANSUL Fire Suppression System is a premium solution designed to protect commercial kitchens and cooking equipment from fire hazards. It is an automatic, pre-engineered system trusted globally for its reliability and effectiveness in suppressing fires quickly, minimizing damage and downtime. Recognized for its advanced ANSULEX Low pH liquid agent, the system ensures rapid fire suppression, cooling of surfaces, and easy cleanup, making it a preferred choice for restaurant fire safety.

Overview of the ANSUL R-102 System

The ANSUL R-102 System is an automatic, pre-engineered fire suppression solution designed for commercial kitchens. It protects cooking appliances, hoods, ducts, and grease extraction systems. Utilizing the ANSULEX Low pH liquid agent, it rapidly suppresses fires and cools surfaces, ensuring quick recovery. Engineered for reliability, the system is installed by authorized distributors, offering tailored protection for high-risk kitchen environments.

Purpose and Functionality of the System

The ANSUL R-102 System is designed to protect commercial kitchens from fire hazards. It automatically detects and suppresses fires, preventing reflash with its ANSULEX agent. The system provides reliable fire protection, ensuring safety and minimizing downtime in high-risk kitchen environments through its advanced functionality.

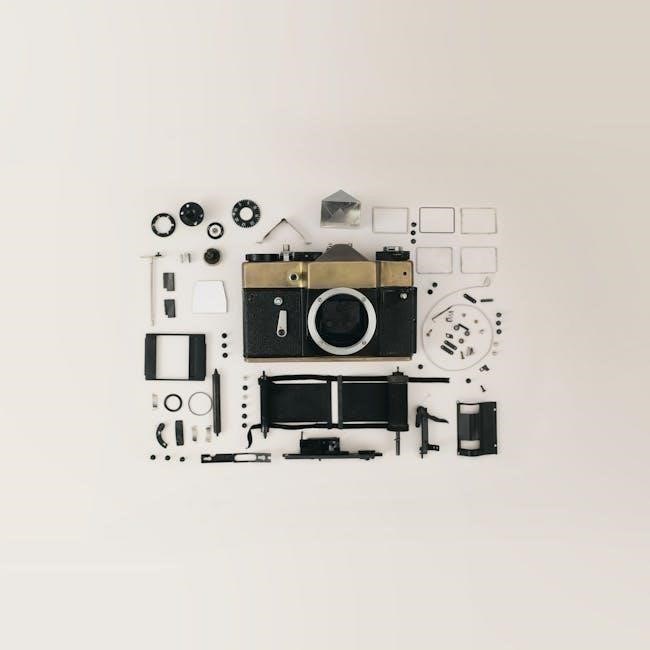

Key Components of the ANSUL R-102 Fire Suppression System

The system includes ANSULEX Low pH liquid suppressant, a storage tank, nitrogen cartridge, actuator, and distribution nozzles, designed to quickly suppress fires in kitchen environments.

ANSULEX Low pH Liquid Fire Suppressant

ANSULEX is a revolutionary, equipment-friendly fire suppressant with a near-neutral pH. It rapidly extinguishes flames, cools hot surfaces to prevent re-flash, and minimizes cleanup efforts. Designed for the ANSUL R-102 system, ANSULEX ensures quick recovery after a fire incident, reducing downtime and damage in commercial kitchens. Its effectiveness and ease of use make it a preferred choice for fire safety professionals.

System Design and Mechanical Components

The ANSUL R-102 system features a flexible design with key mechanical components like the ANSUL tank, nitrogen cartridge, and sopanifier. These components work together to ensure reliable fire suppression. The system includes piping, fusible links, and nozzles, all precisely engineered for seamless operation. Its pre-engineered layout allows for efficient installation and maintenance, ensuring optimal performance in protecting restaurant kitchens and ventilation systems from fire hazards.

Fusible Links and Actuation Mechanisms

Fusible links are critical in the ANSUL R-102 system, designed to activate suppression when exposed to high temperatures, ensuring prompt response to fire threats. The actuation mechanisms, including manual pull switches and automatic sensors, trigger the release of the ANSULEX agent. These components are engineered for reliability, providing a swift and effective fire suppression response, essential for protecting kitchen equipment and ventilation systems.

How the ANSUL Fire Suppression System Works

The ANSUL system detects fires through heat or smoke, automatically releasing the ANSULEX agent to suppress flames and cool surfaces, ensuring rapid and effective fire control.

Detection and Activation Process

The ANSUL system employs heat and smoke detectors to identify potential fires. Upon detection, the system activates automatically, releasing the ANSULEX agent through nozzles. This process is rapid, ensuring flames are suppressed quickly. Additionally, a manual pull switch allows for immediate activation if needed. The system’s design ensures early detection and swift response, critical for minimizing fire-related damage in high-risk environments like commercial kitchens.

Suppression Agent Deployment

The ANSUL system deploys the ANSULEX Low pH liquid suppressant through fixed nozzles, releasing the agent upon fire detection. This agent rapidly suppresses flames and cools surfaces, preventing reflash. Its near-neutral pH formulation minimizes damage to equipment, making it ideal for kitchen environments. The suppressant creates a vapor-securing blanket, ensuring comprehensive fire control and reducing cleanup efforts after discharge.

Post-Discharge Procedures and Cleanup

After discharge, the ANSULEX agent requires immediate cleanup to ensure safety and system readiness. The water-soluble, low-pH liquid suppressant is non-corrosive, making cleanup easier than with dry chemicals. The affected area should be thoroughly washed with water to remove residue. Additionally, the system must be recharged and serviced by an authorized ANSUL distributor to restore functionality and ensure future protection.

Applications and Use Cases

The ANSUL Fire Suppression System is ideal for commercial kitchens, protecting cooking equipment, hoods, ducts, and ventilation systems. It effectively mitigates high-risk fire hazards in these environments.

Restaurant Kitchens and Cooking Equipment

The ANSUL Fire Suppression System is specifically designed to protect restaurant kitchens and cooking equipment, including fryers, griddles, and range tops. It effectively suppresses grease fires, which are common in commercial kitchens, by using the ANSULEX Low pH liquid agent. This system ensures rapid fire detection and suppression, providing 24/7 protection for high-risk kitchen environments. Its pre-engineered design makes it ideal for installation in busy restaurants, ensuring safety and compliance with fire codes.

Commercial and Industrial Ventilation Systems

The ANSUL Fire Suppression System is tailored to protect commercial and industrial ventilation systems, including hoods, ducts, and plenums. It prevents fire from spreading through these critical areas, which are prone to grease buildup and heat. The system’s ANSULEX agent quickly suppresses fires, cools surfaces, and minimizes damage. This ensures uninterrupted operation and safety in industrial settings, making it a vital component for fire protection in ventilation infrastructure.

Grease Extraction and Duct Protection

Grease-laden ducts and extraction systems are high-risk fire zones. The ANSUL Fire Suppression System specifically addresses these hazards, providing comprehensive protection for grease extraction equipment and ductwork. Its ANSULEX agent effectively suppresses grease fires, cools surfaces, and prevents re-flash. This specialized protection ensures the integrity of duct systems, reducing fire-related risks and maintaining operational continuity in commercial kitchens and industrial facilities.

Installation and Maintenance Requirements

The ANSUL system must be installed by authorized distributors, ensuring proper setup and compliance with safety standards. Regular maintenance, including inspections and recharge checks, is essential for optimal performance and reliability.

Pre-Installation Checks and Setup

Before installation, ensure the site is evaluated for fire hazards and system compatibility. Properly design and place components like the tank, nozzles, and detection devices. Verify compliance with local fire codes and standards. Conduct a thorough review of the system layout to ensure coverage of all protected areas, including cooking equipment and ventilation systems. The system must be fully charged and certified by an authorized ANSUL distributor prior to activation.

Regular Maintenance and Inspection Guidelines

Regular maintenance is crucial for optimal performance. Inspect components like fusible links, nozzles, and piping for damage or blockages; Ensure the ANSULEX agent levels are within specifications and replace expiring components. Conduct system tests annually, including actuation and discharge simulations. Maintain detailed records of inspections and tests; Always follow the manufacturer’s instructions and schedule maintenance with an authorized ANSUL distributor to ensure compliance and reliability.

ANSUL R-102 User Guide and Responsibilities

Understand system operation, maintenance, and emergency procedures. Ensure regular inspections, proper agent levels, and timely recharges. Follow manufacturer guidelines and keep records of all maintenance activities for compliance and safety.

End-User Responsibilities and Safety Precautions

End-users must ensure the ANSUL R-102 system is regularly inspected and maintained by authorized personnel. Proper training on system operation and emergency procedures is essential. Avoid tampering with components and ensure all safety precautions are followed. Keep the area around the system clear of obstructions and ensure manual pull stations are easily accessible. Adhere to manufacturer guidelines for optimal performance and safety.

Emergency Procedures in Case of Fire

In case of a fire, the ANSUL R-102 system automatically activates, discharging the ANSULEX agent to suppress flames and cool surfaces. Manually pull the actuation handle if safe. Evacuate the area, switch off power, and ventilate to prevent re-flash. Do not reuse cooking equipment until the system is inspected and reset by authorized personnel. Follow all safety protocols to ensure effectiveness and safety.

Historical Development and Evolution

The ANSUL system evolved from the R-100, the first dry chemical system for restaurants, to the advanced R-102 with ANSULEX, enhancing kitchen fire protection.

From R-100 to R-102: Advancements in Technology

The ANSUL R-100, the first dry chemical system for restaurant hood protection, paved the way for the R-102. The R-102 introduces the ANSULEX Low pH liquid agent, offering improved fire suppression, faster cooling, and easier cleanup. This advancement enhances effectiveness in high-risk kitchen environments, reducing downtime and damage, making it a superior choice for modern fire safety needs.

Industry Recognition and Compliance Standards

The ANSUL Fire Suppression System is widely recognized by restaurant owners, insurance companies, and fire inspectors for its reliability and effectiveness. It meets stringent industry standards, including NFPA 17A, UL 300, and local fire codes, ensuring compliance and trust. The system’s adherence to these standards underscores its commitment to safety, making it a preferred choice for fire protection in professional kitchens worldwide.

Comparison with Other Fire Suppression Systems

The ANSUL Fire Suppression System stands out with its wet chemical technology, offering superior effectiveness in high-risk kitchen environments compared to traditional dry chemical systems. Its global recognition and efficient suppression capabilities make it a preferred choice for commercial fire safety, ensuring minimal damage and downtime.

Advantages Over Dry Chemical Systems

The ANSUL Fire Suppression System offers significant advantages over dry chemical systems, primarily through its use of the ANSULEX Low pH liquid suppressant. This agent is equipment-friendly, reducing corrosion and damage to kitchen appliances. It also provides superior cooling to prevent fire re-flash and ensures faster cleanup, minimizing operational downtime. Additionally, ANSULEX’s near-neutral pH makes it safer for surfaces and environments compared to traditional dry chemicals.

Effectiveness in High-Risk Kitchen Environments

The ANSUL Fire Suppression System excels in high-risk kitchen environments due to its rapid detection and suppression capabilities. Designed specifically for professional kitchens, it protects cooking equipment, hoods, and ducts from grease and oil fires. The ANSULEX Low pH liquid agent rapidly extinguishes flames, cools surfaces, and prevents re-flash, ensuring enhanced safety and minimal damage in high-hazard cooking areas.

Case Studies and Real-World Applications

The ANSUL Fire Suppression System has proven effective in numerous real-world scenarios, particularly in high-risk commercial kitchens. Its ability to suppress grease and oil fires quickly has made it a trusted solution for restaurants and industrial cooking facilities, ensuring safety and minimizing downtime in critical environments.

Success Stories in Restaurant Fire Protection

The ANSUL R-102 system has successfully protected numerous restaurants from devastating grease and oil fires. In a busy restaurant kitchen, the system detected a fire in the ductwork and suppressed it within seconds, preventing extensive damage. Another high-end kitchen experienced a fire during peak hours, but the ANSUL system activated seamlessly, ensuring minimal downtime and continued operations. These real-world applications highlight its reliability and effectiveness in safeguarding lives and property.

Industry-Specific Implementations and Results

The ANSUL R-102 fire suppression system is extensively implemented in restaurants and commercial kitchens to protect cooking equipment and ventilation systems. Its effectiveness in quickly suppressing grease and oil fires has significantly reduced fire-related incidents. By utilizing the ANSULEX Low pH liquid agent, the system ensures rapid action and easy cleanup, contributing to safer environments and uninterrupted business operations.

Future Trends and Innovations

Emerging technologies in fire suppression, such as water-atomizing systems and eco-friendly agents, are being explored to enhance efficiency and sustainability in ANSUL systems, ensuring better fire protection solutions.

Emerging Technologies in Fire Suppression

ANSUL is advancing fire suppression with innovative solutions like the AQUASONIC Water-Atomizing System, optimizing water usage for Class B fires. The CHECKFIRE 210 Detection System integrates seamlessly with liquid agents, enhancing accuracy. Sustainability efforts focus on eco-friendly suppressants, reducing environmental impact. These technologies aim to improve efficiency, safety, and environmental compliance, setting new standards in fire protection.

Sustainability and Environmental Considerations

The ANSUL Fire Suppression System prioritizes eco-friendly solutions, such as the ANSULEX Low pH agent, which is equipment-friendly and minimizes environmental impact. The system’s efficient suppression reduces water and chemical usage, aligning with sustainability goals. ANSUL also adheres to strict environmental regulations, ensuring its products are designed to protect both people and the planet, making it a responsible choice for modern fire safety needs.